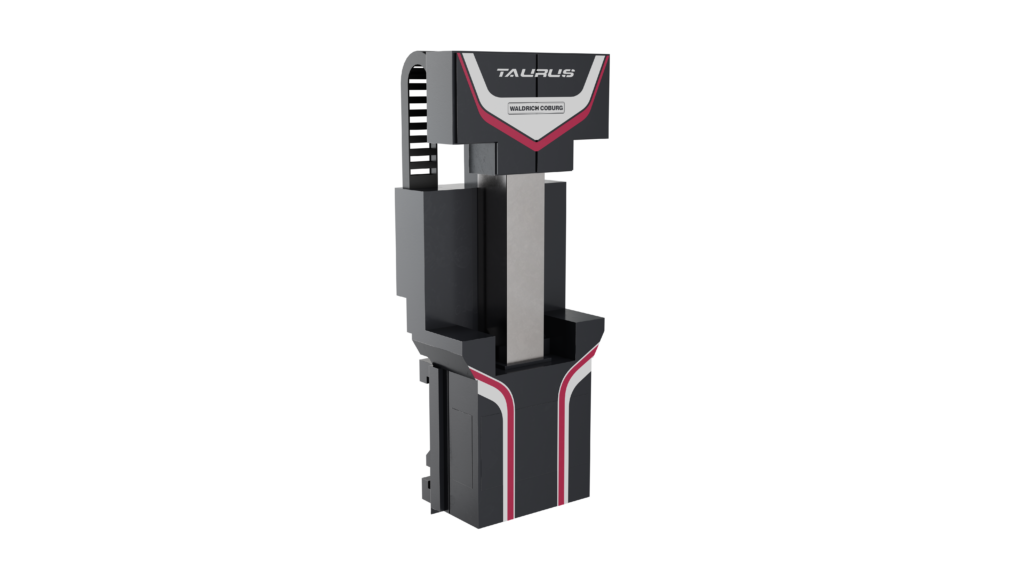

The only wear free machine in its class.

Highest precision in the category. Aesthetic appeal that is unmatched.

Variety, flexibility and precision combined in a unique technology from WALDRICH COBURG!

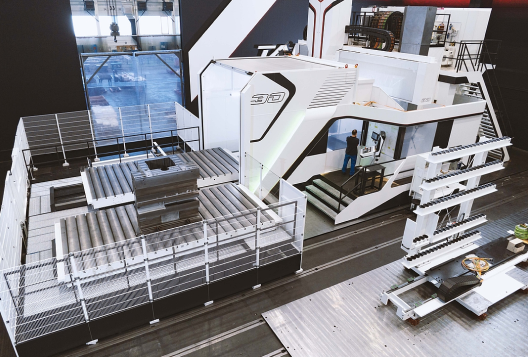

At the center of our TAURUS universe are the many possibilities that our TAURUS & TAURUS Gemini already offer today. But we are still setting new standards by expanding the dimensions of flexibility, versatility and productivity in the processing of workpieces,

have redefined. With the TAURUS universe, we proudly present the development of our machines that will revolutionize your manufacturing world — sustainably.

Our TAURUS has been recognized for many years for its impressive performance and precision. But now we are going one step further, because through our engineering we have further expanded the scope for creativity and innovation once again.

TAURUS — the ideal machining center for the following applications:

Minimal operating costs thanks to energy-efficient design.

Increased productivity due to short non-productive times and best ergonomics. Low hourly rates with the highest performance result in the best price-milling ratio.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

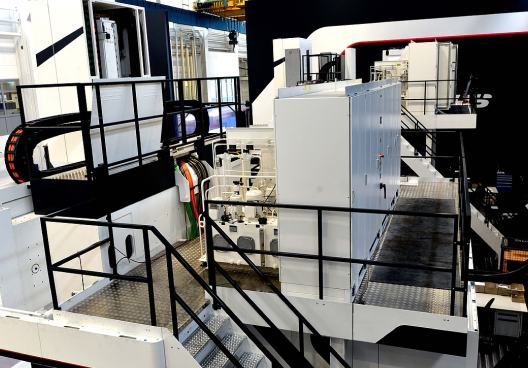

Our optional two-table or double-table design allows you, to set up in parallel for machining or to machine extremely long workpieces. Your productivity reaches new heights while remaining flexible.

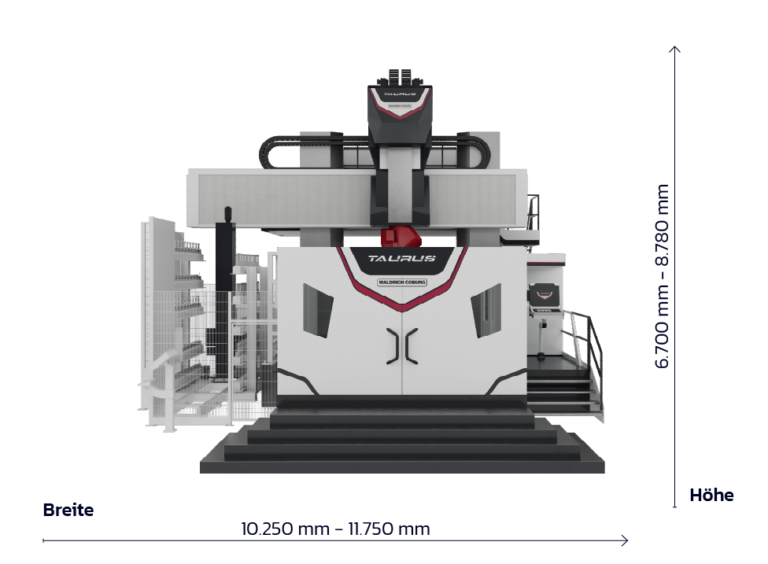

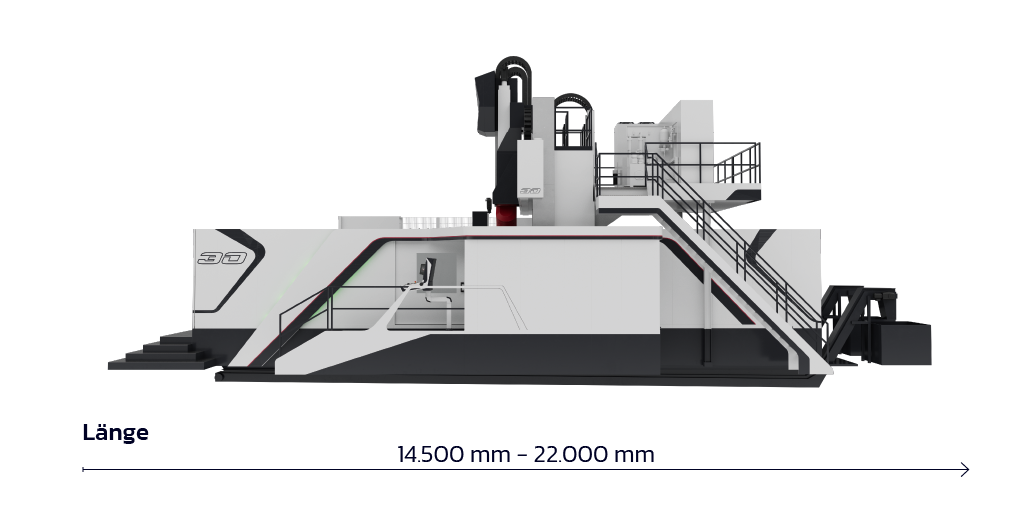

With additional table lengths, clearance widths and clearance heights, we give you the freedom to machine an even wider range of workpieces on our machines. There are no limits.

Just send us your contact details — we will get back to you.

Machine size depends on the configuration

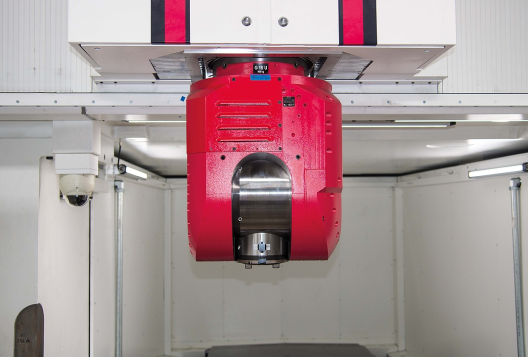

All frame components are made of high-quality gray cast iron with the best damping properties. The generously dimensioned wall thicknesses and the load-oriented ribbing guarantee outstanding rigidity. Both are the basis for performance in machining at very high precision.

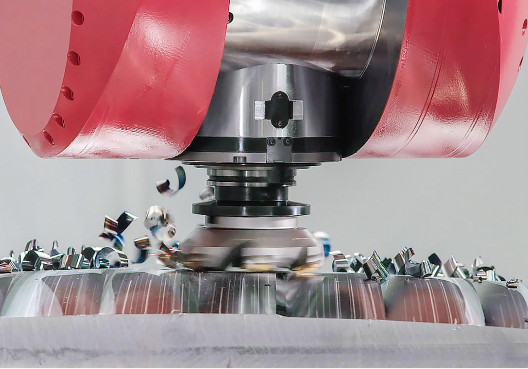

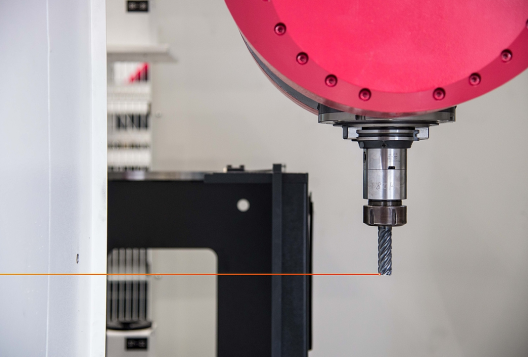

Wear-free hydrostatic guides in the crossbeam, W‑axis and RAM guarantee trouble-free production.

Absolute position measuring systems and modern digital drives enable precise control.

Simply cleverly done: all the advantages of hydrostatic guides, such as accuracy and milling behavior, are used and the energy balance is improved.

The excellent damping properties of the hydrostatics support the machining process, and the guides are highly accurate and wear-free. The temperature of the hydrostatic oil is tracked to the room temperature.

This maintains the high machine accuracy even with changing ambient temperatures. Separate energy-consuming temperature control equipment can be eliminated. The machine remains consistently accurate even in an adverse environment.

State-of-the-art drive technology and absolute measuring systems enable energy-optimized operation with high precision and low maintenance. Energy recovery systems have been in use at WALDRICH COBURG for decades.

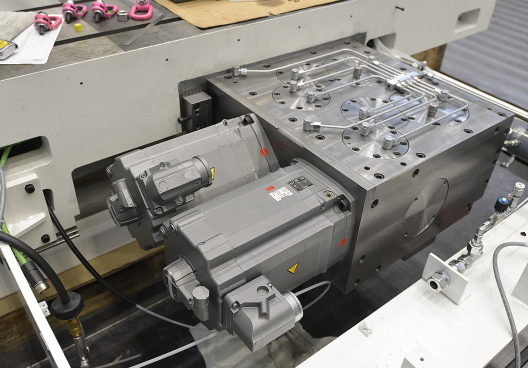

The space-optimized self-built gearbox of the X‑axis sits on the machine table. The high in-house production rate ensures a supply of spare parts even after 20 years.

The two feed motors of the X‑axis are water-cooled, thus preventing heat from entering the machine.

For automatic replacement or permanent installation in the spindle units for the US-HF‑1

Just send us your contact details — we will get back to you.

With 100 tools in the basic configuration and the expansion option to 200 places, a high degree of flexibility is also achieved in the tool area. The very short tool change times reduce non-productive time to a minimum.

The machining units of the TAURUS are produced in Coburg. So the TAURUS can be adapted to your workpiece. In the automatic changing system, 4 storage places for processing units are available.

The coolant cleaning system is integrated on the supply platform. A compact belt filter system is used, which can be flexibly adapted to customer requirements. Here, too, we pay attention to low energy consumption and use frequency-controlled booster pumps for the internal and external coolant supply. By using a screw pump, the pressure of the internal coolant supply can be increased to 70 bar, as an alternative to the standard version.

Design und Function!

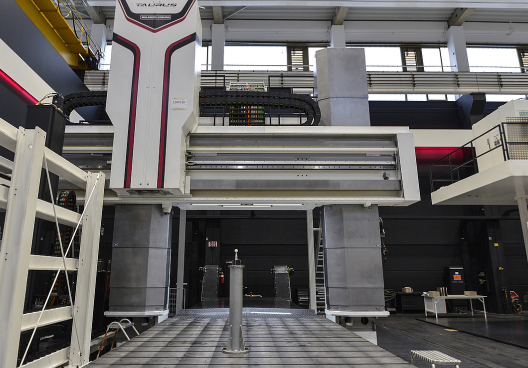

The TAURUS guarding system is more than just splash and chip protection. The operator‘s raised platform, the chip conveyors and the gratings next to the table are integrated into the guarding.

The operator has a good clear view of the machining process through the large windows next to the operating panel. The sliding door into the machine has a wide opening.

The large, but light hinged-doors at the front of the machine assist workpiece loading.

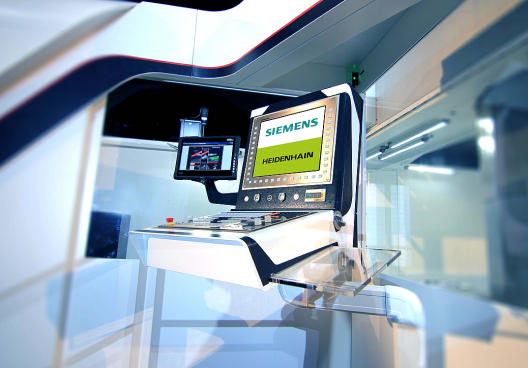

According to requirements, TAURUS can be delivered with either a Heidenhain or Siemens control.

Thereby you can operate TAURUS using your familiar control systems.

Working with TAURUS is great!

Because of the large display and the manufacturer’s original keyboard, operating TAURUS is a pleasure.

The whole control station can be swiveled and the angle of the keyboard can be adjusted.

With the optionally available video camera or InPro productivity package, a separate tablet and docking station with additional functions is also included for the operator’s use.

The operator is pleased with the space-saving compact design. All supply units are located on the energy box.

Regenerative drive technology, wear-free guides and the combination of the supply units in the energy box facilitate operation and maintenance work. Combined with modern tools like InPro software, energy recovery drive technology, and wear free guildeways the end user will clearly realize lower operating costs.

This package includes a cleaning station for the tool flange and taper. In addition, tool breakage detection using a laser is included.

The use of tool breakage detection reduces tooling costs and enables unmanned production.

An optional pallet changer is available to allow part set-up in parallel with part machining. The fast double carrier reduces non-productive time. It only takes 3 minutes to exchange pallets. Extended chip conveyors keep the set-up area clean.

Fully enclosed guarding for the machine is included in the price of the pallet system.

The dome-type video camera is located in the working area and allows the operator to view the far side of the workpiece.

The camera has swivel and zoom functions. The picture is shown on the InPro tablet.

InPro, the Interactive Production support allows ergonomic operation, increases the machine availability and contributes to machine safety. Maintenance personnel are assisted by a menu-guided system, the interactive diagnostics help for a speedy error search and the MDR gives information on machine use. Fixture sheets, NC program management etc. are connected to a modern network. WALDRICH COBURG has used this for more than 15 years and Teleservice for more than 30 years.

Du möchtest Teil des WALDRICH COBURG Teams werden? Schicke uns einfach Deine Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail an jobs@waldrich-coburg.de. Wir freuen uns darauf, Dich kennenzulernen!

Du möchtest Teil des WALDRICH COBURG Teams werden? Schicke uns einfach Deine Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Dich kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Das Thema Bewerbungen schreiben steht an und du hast keinen Plan, wie du eine gute Bewerbung für einen technischen Beruf hinkriegen sollst? Wir haben hier genau das Richtige für dich! Mit unseren Tipps und Tricks sowie der Checkliste wird deine Bewerbung ein Erfolg.

Deine Bewerbungsunterlagen sollten ordentlich strukturiert und übersichtlich sein. Bei technischen Berufen brauchst du:

Das Anschreiben (oder auch Motivationsschreiben genannt)

Tipp: Kontrolliere die Rechtschreibung in deinen Bewerbungsunterlagen!

Deinen tabellarischen Lebenslauf

Deine letzten beiden (Schul-)Zeugnisse

Bescheinigungen für Praktika und ehrenamtliche Tätigkeiten

Tipp: Achte darauf, die Dateien, die du anfügst, klar zu benennen, z.B. Lebenslauf_Nachname, Vorname.

Verwende außerdem eine E-Mail-Adresse mit Klarnamen, z.B. max.mustermann@web.de statt schnuggihase23@web.de.

Das Bewerbungsgespräch dauert bei den meisten Unternehmen ca. 30 - 45 min.

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Du möchtest Teil des WALDRICH COBURG Teams werden? Schicke uns einfach Deine Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Dich kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Dein Studium endet mit dem Titel Bachelor of Engineering in der Fachrichtung Elektro-/Informationstechnik.

Überall dort, wo Maschinen und technische Anlagen entwickelt und gebaut, betrieben und instandgesetzt werden, warten Arbeitsplätze auf Dich - schon während Deines Studiums. Nach dem Studium öffnen sich für Dich Türen in sämtlichen technischen Bereichen mit hochqualifizierten Positionen.

Außerdem unterstützen wir Dich bei Fragen zu Deinen Studieninhalten.

Du möchtest Teil des WALDRICH COBURG Teams werden? Schicke uns einfach Deine Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Dich kennenzulernen!

Dein Studium endet mit dem Titel Bachelor of Engineering in der Fachrichtung Maschinenbau.

Überall dort, wo Maschinen und technische Anlagen entwickelt und gebaut, betrieben und instandgesetzt werden, warten Arbeitsplätze auf Dich - noch während Deiner Studienzeit. Nach dem Studium öffnen sich für Dich Türen in sämtlichen technischen Bereichen mit hochqualifizierten Positionen.

Außerdem unterstützen wir Dich bei Fragen zu Deinen Studieninhalten.

Du möchtest Teil des WALDRICH COBURG Teams werden? Schicke uns einfach Deine Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Dich kennenzulernen!

Beschreiben Sie bitte das Berufsfeld, in welchem Sie bei uns tätig werden wollen.

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Du entwickelst digitale Lösungen in verschiedenen Unternehmensbereichen und lernst den Umgang mit den IT-Systemen unserer Maschinen.

Wir setzen dich nicht nur in der Steuerungstechnik, sondern auf Wunsch auch in anderen Abteilungen und bei Projekten ein. Sogar eine Spezialisierung in den Fachbereichen Anwendungsentwicklung, Systemintegration, Digitale Vernetzung oder Daten- und Prozessanalyse ist möglich.

Schon ab dem ersten Tag bekommst du eine tolle Ausbildungsvergütung nach dem Tarif der Bayerischen Metall- und Elektroindustrie und bist damit finanziell unabhängig.

Abgestimmt auf Ihr Personal werden wichtige fachbereichsspezifische Grundkenntnisse zur Bedienung, Wartung/Instandhaltung bzw. zur selbständigen Erstellung von Bearbeitungsprogrammen vermittelt.

Zusätzlich unterstützen wir Sie auf Wunsch gerne mit einer Produktionsbegleitung beim Start Ihrer Produktlinie. Unser erfahrenes Fachpersonal steht hier Ihren Mitarbeitenden mit Rat und Tat zur Seite.

Give your employees the knowledge and skills they need to handle the machine properly and maintain it with care.

We recommend our entry-level package for this.

This includes one training for operating personnel and one for maintenance personnel (mechanical and electrical).

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

Sie sind Elektriker oder Elektroniker (m/w/d) und möchten gerne weltweit tätig sein?

Wir bilden Sie im Rahmen Ihrer Einarbeitung weiter. Wachsen Sie mit uns und werden Sie zum Inbetriebnehmer (m/w/d) bei WALDRICH COBURG.

Sie möchten Teil des WALDRICH COBURG Teams werden? Schicken Sie uns einfach Ihre Bewerbungsunterlagen (Anschreiben, Lebenslauf, Qualifikationen, etc) per E-Mail. Wir freuen uns darauf, Sie kennenzulernen!

You will be employed by us in small, medium and large-scale production. You will work on milling, turning and grinding machines and also have the chance to produce workpieces on our in-house WALDRICH COBURG machining centers. You'll machine gearbox housings, shafts, spindles, stands, beds and other high-precision machine components.

You can plan production sequences, select tools and determine cutting data, as well as precisely set up machines and monitor the production process. You create programs, tool and clamping plans for CNC machines (Computerized Numerical Control).

After your successful training you have the best chances for a permanent position.

From the very first day, you will receive a great apprenticeship pay according to the tariff of the Bavarian metal and electrical industry and are thus financially independent.

You are involved in the development of equipment and machinery. You create three-dimensional data models and technical documentation for components and assemblies and work closely with engineers and designers.

You accompany the development of a product from the first idea to the finished machine. For this purpose, you will receive intensive instruction in the basics of construction, design and calculation as part of your training. You work with CAD systems and programs. Learned detailed knowledge of manufacturing processes and conditions will allow you to create drawing documentation of the products. Expertise in materials technology, manufacturing, assembly and joining processes as well as the impeccable handling of molds and design rules round off your profile.

From the very first day, you will receive a great apprenticeship pay according to the tariff of the Bavarian metal and electrical industry and are thus financially independent.

As a result of the high competitive pressure, there is often hardly any time left to carry out maintenance on the company's own machines and means of production. We therefore also offer an abbreviated machine inspection by a qualified technician.

Due to capacity utilization or cost-cutting measures, the machines are pushed to their performance limits and the risk of unplanned downtime in conjunction with high maintenance costs is accepted. Our one-day basic check provides you with important information about the general condition of your machine tool. The risk of failure can already be drastically reduced by a simple and, above all, structured service check.

We will be happy to advise you on the maintenance and servicing of your system.

To be able to react as quickly as possible to malfunctions, we have a large number of mechanical and electrical spare parts in stock. In addition we will be happy to put together a customized spare parts package for your inventory.

Even for older machines, the supply of spare parts is ensured by our extensive documentation. Should individual spare parts no longer be available, we can fall back on a large number of tried and tested replacement solutions.

For reliable production planning it is necessary to identify and to take into account impending maintenance and repair measures at an early stage.

Regular maintenance is the most important preventive measure to ensure high system availability and therefore cost-effective operation. We recommend a maintenance interval of six to twelve months depending on the machine type and application. For improved predictability, WALDRICH COBURG can develop a specific maintenance contract for your machine.

Even if there are no current problems, regular inspections to record the condition of the machine should be planned. Our specially qualified and trained personnel undertake these inspections based on machinery-specific inspection lists, and prepare a detailed report with recommendations.

Over time, the machine geometry can change due to various effects. Straightening work is therefore essential and is carried out quickly and reliably by our experienced employees.

To be able to react as quickly as possible to malfunctions, we have a large number of mechanical and electrical spare parts in stock. In addition we will be happy to put together a customized spare parts package for your inventory.

Even for older machines, the supply of spare parts is ensured by our extensive documentation. Should individual spare parts no longer be available, we can fall back on a large number of tried and tested replacement solutions.

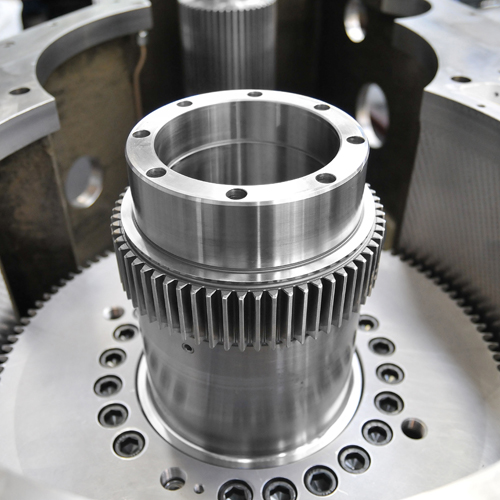

Even if you do not own a WALDRICH COBURG, you do not need to forego high precision components.

Our satisfied customers produce products in a wide range of sectors: Power station components, diesel engines, rolling mill plants, printing presses and machine tools, aerospace, general mechanical engineering, and much more.

Take advantage of our know-how from this wide range of applications and benefit from our modern, well-equipped machinery for your contract machining.

| Maschinetype | Manufacturer | Machining Area |

|---|---|---|

| CNC - Machining Center | Dixi | X=1.200 Y=1.100 Z=1.100 |

| CNC – Machining Center | Hermle | X=800 Y=800 Z=700 |

| CNC – Machining Center | Hermle | X=1.000 Y=1.100 Z=750 |

| CNC - Horizontal Machining Center | Bohle | X=1.700 Y=1.400 Z=1.100 |

| CNC - Horizontal Machining Center | Bohle | X=1.700 Y=1.400 Z=1.100 |

| CNC - Horizontal Machining Center | WALDRICH COBURG | X=3.000 Y=2.000 Z=4.000 |

| CNC - Portal Milling Machine | WALDRICH COBURG | X=12.500 Y=2.500 Z=2.500 |

| CNC - Portal Milling Machine | WALDRICH COBURG | X=7.000 Y=2.500 Z=2.500 |

| CNC - Portal Milling Machine | WALDRICH COBURG | X=16.000 Y=3.000 Z=3.000 |

| CNC - Portal Milling Machine | WALDRICH COBURG | X=27.200 Y=3.500 Z=4.000 |

| CNC - Boring mill | Wotan | X=1.050 Y=600 Z=560 |

| CNC - Boring mill | Wotan | X=1.700 Y=1.700 Z=1.250 |

| CNC - Boring mill | Wotan | X=2.500 Y=1.250 Z=1.000 |

| CNC - Gear hobbing machine | TOS | 850 x D900 |

| NC - Milling Machine | Kekeisen | X=3.000 Y=1.000 Z=1.000 |

| NC - Milling Machine | Reckermann | X=1.500 Y=500 Z=450 |

| TNC-Universal Milling Machine | Maho | X=1.200 Y=500 Z=500 |

| Maschinetype | Manufacturer | Machining Area |

|---|---|---|

| External cylindrical grinder | ELB | 1.000 x D250 |

| Internal cylindrical grinder | Schandt | 125 x D175 |

| Flat Grinding Machine | ELB | X=2.000 Y = 750 |

| CNC - Surface Grinder | WALDRICH COBURG |

X=9.000 |

| Cylindrical grinding machine | Danobat | 2.500 x D600 |

| CNC-Cylindrical grinding machine | Kellenberger | 1.500 x D225 |

| CNC-Cylindrical grinding machine | Kehren | Rundtisch Ø1.000; Z=1.000 |

| Gear profile grinding machine | Kapp Niles | 400 x D800; Innenschleifarm für Innenverzahnungen |

| Maschinetype | Manufacturer | Machining Area |

|---|---|---|

| CNC-lathe | Heyligenstaedt | 2.000 x D420 |

| NC-Cycle lathe | Weiler | 4.000 x D830 |

| NC-Cycle lathe | Weiler | 2.000 x D280 |

| Centre lathe | Böhringer | 2.000 x D520 |

| Centre lathe | Heidenreich | 1.500 x D280 |

| Centre lathe | Weiler | 2.000 x D345 |

| Maschinetype | Manufacturer | Machining Area |

|---|---|---|

| 3D measuring machine | Zeiss Accura 14 | X=1.600 Y=2.400 Z=1.400 |

| 3D measuring machine | Zeiss Prismo 10 |

X=1.200 |

| Maschinetype | Manufacturer | Machining Area |

|---|---|---|

| Stoßmaschine | Ravensburg | Z = 600 |

| Läppmaschine |

Whether it is an on-site visit to our customer’s facility, or the repair work is completed in our specialized departments; our highly qualified service staff can solve every problem.

Along with our decades of experience, you profit from our comprehensive machine documentation. Detailed drawings and part lists are the basis for the shortest possible lead and repair times.

Due to capacity utilization or cost-cutting measures, maintenance and service of machining units are often forgotten.

The consequences are unplanned downtimes in connection with high repair costs and long downtimes of the processing units.

The risk can already be drastically reduced by specific maintenance intervals with repair recommendation of your processing units. Delivery and repair times are reduced to a minimum.

We will be happy to advise you in a personal meeting and submit an individual maintenance plan for your processing units.

Since 1986 our service engineers, located in Coburg, have been able to access Waldrich Coburg machinery installed around the world to diagnose the cause of any malfunctions that occur. This statement applies to all controller types and various configurations implemented.

Our experience shows that a large portion of the malfunctions can be rectified quickly with the aid of teleservice, either directly or in collaboration with your personnel on site.

The WALDRICH COBURG Remote Service gives you the opportunity to connect quickly and efficiently with the specialists at the Coburg site, who can connect directly to your machine, thereby reducing downtimes and enabling faults to be rectified immediately, if possible, without the need for a service technician to travel to your location.

You manufacture device parts and assemblies for machines and production plants, set them up or convert them.

You monitor and optimize manufacturing processes and take on repair and maintenance tasks.

Industrial mechanics are employed by us in all assembly areas, including outdoor assembly.

You have mastered the basics of metalworking and various assembly techniques. Pneumatics and hydraulics are not foreign words to you. You assemble device parts and assemblies for machines, set them up or convert them. You monitor machine functions and take on repair and maintenance tasks.

Afterwards, you have the opportunity to train as a master, technician, engineer or assembly manager on projects abroad.

From the very first day, you will receive a great apprenticeship pay according to the tariff of the Bavarian metal and electrical industry and are thus financially independent.

You install, maintain and repair electrical operating, production and process systems, from switching and control systems to power supply systems.

You will be employed by us wherever production and operating equipment is used and maintained.

You can program our high-bay warehouse, have very good chances of obtaining a permanent position and can train to become a master or technician.

From the very first day, you will receive a great apprenticeship pay according to the tariff of the Bavarian metal and electrical industry and are thus financially independent.

Every machine tool is subject to wear and tear during operation. The availability of a machine drops over the years due to the need for often unplanned repairs. The supply of spare parts, especially electrical components, becomes increasingly difficult with advancing age. The lack of spare parts can render the entire machine unusable. Reliable production planning becomes impossible.

Based on your requirements we develop the optimal custom solution to restore geometrical accuracy, technical availability, increase productivity, and safeguard the supply of spare parts. Furthermore, retrofitting can be used to significantly increase the performance of the machine.

The financial expense for a modernization, depending on the scope, is between 30-60% of the investment in a comparable new machine, and therefore represents the more cost-effective alternative.

Advice, planning, design, implementation of electrical and mechanical measures, programming, acceptance, and support are provided directly from a single source at Waldrich Coburg, even for the most complex projects.

In order to be able to act as quickly as possible in case of malfunctions, we have a large number of mechanical and electrical spare parts in stock for you. In addition we will be happy to create individually designed spare parts packages for your own stockpiling.

Even for older machines, the supply of spare parts is ensured due to our extensive documentation. If individual spare parts are no longer available, we can draw on a wide range of tried-and-tested replacement solutions.