The reliability of our machine tools is essential for you to be able to produce efficiently. To ensure the highest quality and shortest response times, WALDRICH COBURG has over 100 experienced service employees working for you around the world and around the clock.

Regular service Improved availability Planable costs

Services

Retrofit

Every machine tool is subject to wear and tear during operation. The availability of a machine drops over the years due to the need for often unplanned repairs. The supply of spare parts, especially electrical components, becomes increasingly difficult with advancing age. The lack of spare parts can render the entire machine unusable. Reliable production planning becomes impossible.

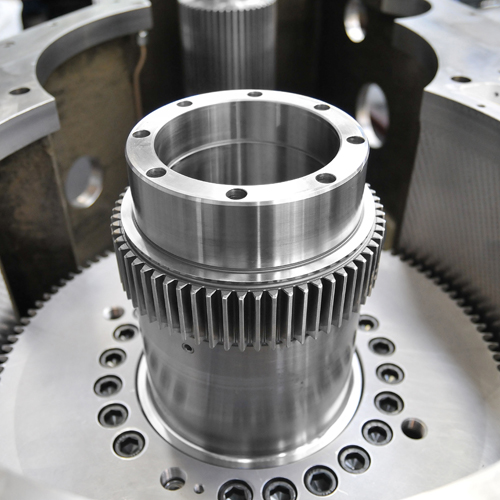

Spare parts

To be able to react as quickly as possible to malfunctions, we have a large number of mechanical and electrical spare parts in stock. In addition, we would be pleased to prepare an individually designed spare parts package for your inventory.

Even for older machinery the supply of spare parts in ensured due to our comprehensive documentation. If individual spare parts are no longer available, we can draw on a large number of tried and tested substitute solutions.

Remote Service

Since 1986 our service engineers, located in Coburg, have been able to access Waldrich Coburg machinery installed around the world to diagnose the cause of any malfunctions that occur. This statement applies to all controller types and various configurations implemented.

Our experience shows that a large portion of the malfunctions can be rectified quickly with the aid of teleservice, either directly or in collaboration with your personnel on site.

Repairs

Whether it is an on-site visit to our customer’s facility, or the repair work is completed in our specialized departments; our highly qualified service staff can solve every problem.

Along with our decades of experience, you profit from our comprehensive machine documentation. Detailed drawings and part lists are the basis for the shortest possible lead and repair times.

Mechanical processing

Use our knowhow for machining your large work pieces Even if you do not own a WALDRICH COBURG, you do not need to forego high precision components.

Our satisfied customers produce products in a wide range of sectors: Power station components, diesel engines, rolling mill plants, printing presses and machine tools, aerospace, general mechanical engineering, and much more.

Maintainance / Inspection / Adjustments

For reliable production planning it is necessary to identify and to take into account impending maintenance and repair measures at an early stage.

Regular maintenance is the most important preventive measure to ensure high system availability and therefore cost-effective operation. We recommend a maintenance interval of six to twelve months depending on the machine type and application. For improved predictability, WALDRICH COBURG can develop a specific maintenance contract for your machine.

Even if there are no current problems, regular inspections to record the condition of the machine should be planned. Our specially qualified and trained personnel undertake these inspections based on machinery-specific inspection lists, and prepare a detailed report with recommendations.

Over time, the machine geometry can change due to various effects. Adjustments are therefore imperative and are undertaken quickly and reliably by our experienced staff.

Technical customer consultant

As a result of the high competitive pressure, there is often hardly any time left to carry out maintenance on the company’s own machines and means of production.

Because of workload or cost-cutting measures, the machines are pushed to their performance limits and the risk of an unplanned breakdown in connection with high maintenance costs is accepted.

The risk can already be drastically reduced by a simple and, above all, structured service check. We offer these short assignments exclusively to our customers in Central Europe.

Trainings

Safety and well-trained personnel are the basis for a smooth production process. Due to changing framework conditions and new challenges of our time, this basis is increasingly impaired. Current challenges such as a shortage of skilled workers, generational change and the new digitalized world of work are putting production and its employees to the test.

You want to embrace these changes and respond quickly and well to staff changes, generational shifts and digitized ways of working. We support you in this process.

With our trainings, we want to contribute to a stable, optimized and safe way of working. In doing so, we coordinate with your needs and offer training that is individually tailored to your WALDRICH COBURG machine.

Find the training that suits you

Machine transfer

Whether because of re-structuring or sale, the objective of every machine transfer is to re-commission the machine with as little loss of production as possible.

Profit from our many years of experience with more than 3,000 machine tools and the know-how obtained during the installation, planning, and realization of the most comprehensive projects.

Contact overview

Customer Care

Global Service

- E‑Mail: globalservice@waldrich-coburg.de

- Telephone +49 9561 65 165

Global Service Sales

- E‑Mail: globalservicesales@waldrich-coburg.de

- Telephone: +49 9561 65 195

Global Repairs

- E‑Mail: globalrepairs@waldrich-coburg.de

- Telephone: +49 9561 65 170

Global Spareparts

- E‑Mail: globalspares@waldrich-coburg.de

- Telephone: +49 9561 65 180

Global Retrofits

- E‑Mail: globalretrofit@waldrich-coburg.de

- Telephone: +49 9561 65 190